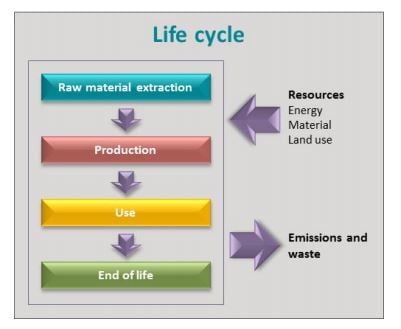

When you’re looking for sustainable packaging in order to offer better justified and firm positions, you want to make sure you have the right tricks and benchmarks for this. The packaging life cycle assessment is one of the best ways, but here, we’ll discuss how this can help you generate better ROI.

How reducing the Materials is the Lowest Hanging Fruit

When looking to design minimalistic packaging that offers protection to the products, you also want to make sure the brand’s message gets included in this. The reduction of this can be by removing different packaging components completely, such as eliminated polybags, instructions, and labels as well. Sometimes, you can also use light weighting components and also getting less gauging paper in this too. Shrinking the packaging is also a good way for you to make sure that you save the material costs, saving money on shipping too. A company needs to adopt this because it definitely offers the highest ROI, and it can be a good way to save a bunch of money without having to do much. The key here is to make sure the damage rate of the product isn’t increased.

Avoid thinking Plastics Are All Bad

When you’re doing the LCA, you probably think that all plastics are bad, but sometimes, it could be a more sustainable choice compared to others, since it offers better protection and pallet stacking, so you need to look at how this fits in with the rest of the materials. You also want to make sure that you also look at the recyclability of this. If you use colorants, dyes, additives, and the like, it can be difficult for recycling in a lot of cases.

Don’t Be Misled

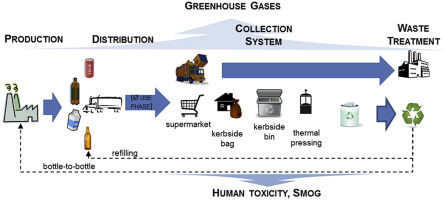

When you do an LCA, you probably think that you’re just looking at a singular components, such as GHG measurements. You need to look at the whole package though, since this is because a lot of times, it isn’t just one component that can be optimized, but rather the whole package, which means that you’re offering implications for this. From this type of perspective, you’re offering more behaviors, and with that, you want to look at different behaviors. Bioplastics are a common example, where you can reduce GHGs, but the water consumption and the aquatic toxicity may rise too. There is also the problems with sugarcane and other options, so you shouldn’t just be looking at the one component, but multiple.

The Shift

You can shift from rigid to flexible in order to lower this, and it’s one of the easiest ways to save money right away. It’s insane how a little bit goes a long way with this sort of thing. Flexible packaging is usually not recyclable, but the different reductions are pretty dramatic compared to other means.

Look at Tradeoffs

You should also look at the different tradeoffs that can happen, such as making different decisions while also ignoring or not understanding the functional and the cost requirements there. It’s important to understand this, and you look at the different tradeoffs, such as the COMPASS and SCORE, letting your trade off the different indicators and attributes with this.

It also isn’t time consuming either. It can take a little bit of time sure, but if you do this, it can take up to 45 minutes, and it can e a good way for you to get immediate results which are incredibly fast to use. And there you have it, everything to know about doing an LCA on products, and what it can do for you too.